Photo 1 + 2: To supplement our systems,

we supply storage bin systems for potatoes and carrots.

| H.

- 21. |

Raw

material treatment before DORNOW plants: |

|

|

with unpeeled potatoes, carrots, onions, other tubers, root vegetables, partially fruit |

||

|

normally steel construction, primed, painted |

||

| 21.4 | Storage Bin Systems |

|

|

|

Photo 1 + 2: To supplement our systems,

we supply storage bin systems for potatoes and carrots. |

|

|

|

|

|

|

|

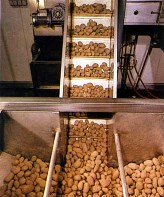

Photo 3-6: Crate tipping device

with bin below. Tubers / root vegetables are

removed via the adjustable conveyor belt. Storage bin and belt function as a dosing bin. |

Other types of storage bins, custom-made according to your request, are available within our product range. |

||

|

|

|

| Photo 7: Hopper belt (Art.-No. 9300)

with dosing function. Contents

approx. 3 t tubers / root vegetables, can be supplied in various

lengths. See also section 21.1 – crate-tipping devices. |

Photo 8: End of the hopper belt (Art.-No. 9300) with “window”. Inclined belt (Art.-No. 3300) to feed other machines. |

|

|

|||

| Photo 9:

Small dosing bin. Belt with adjustable drive. |

Photo 10: Potato crates with a hinged bottom are set onto the storage bin. Potatoes reach an attached system via the connected conveyor belt in a steady and adjustable flow. | |||

|

|

|

||

| Photo 11:

Smaller dosing bin with adjustable discharge unit. |

Photo 12: Dosing bin (stainless steel) for hinged-bottom crates (visible in the background is a waste water separator). | Photo 12.1: Small raw produce bin (amongst others for feeding "big bags") in front of a small peeling line. |

|

|

|

|

Photo 13 + 14: Storage bin with crate feeding unit. Crates are loaded into the lifting device by a hydraulic lifting truck. |

||

|

||

| Photo 15: Major dosing bin (870-3003) with a large storage bin (1,6 m³) for feeding of a DORNOW roller peeling machine. | Photo 16: Dosing

bin with a low height of infeed. |

|