|

H. - 7. |

Storage and dosing technology for wet areas |

|

| for peeled tubers, root vegetables, etc., and for fruit | ||

|

7.1 |

Storage and dosing bins with chain conveyors (0450) |

|

|

|

|

1.3 |

|

1.4 |

1.5 |

1.6 |

|

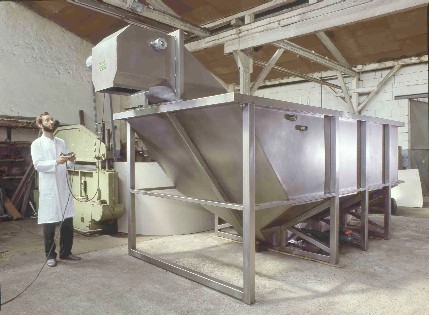

The photos 1.1 to 1.6 show a big storage and dosing bin with integrated chain

conveyor with high return of the chain conveyor.

Content: approx. 1,6 m³. Can be delivered in all

sizes.

|

||

1

1

|

2 |

|

|

Bin for

underwater storage (capacity approx. 1 t) with

adjustable discharge unit, chain conveyor version

(art.no. 0451). |

||

3

3 |

|

5

5 |

|

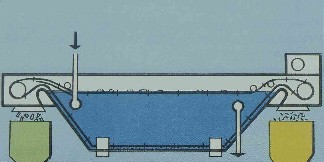

Chain conveyor with storage bin for underwater storage. In this specific case, goods are conveyed diagonally from the storage basin on the "back" of the unit to the top right. |

Small storage bin with preservative liquid. Treated goods are "pushed

up" out of the container. The chain is returned

above water level. |

Bin for

underwater storage, shown here as a mobile unit. The

containers are available in all sizes, up to 10 m in

length. |

7

7

|

|

| Storage bin

with gear unit, at the same time washing and dosing bin, with small part collecting box, type 4.2.3-1400, HR-WA (Art.-No. 0467). |

|

8

8 |

|

|

Chain conveyor with with storage bin conveying

extremely small potato pieces in a mashed potato

production factory. |

Storage bins - equipped with extremely slow-moving chain conveyors

as a means of transportation - are available in all

sizes and versions. |

10

10 |

11

11 |

|

Large bin for

underwater storage with adjustable |

View of a larger bin for underwater storage: the adjustable release device is a chain conveyor. The conveyor is returned above the surface of the water. |

12

12 |

|

| View into the described storage bin. | |

13

13 |

14

14 |

| Storage bin

with high hand-over point. |

Special storage bin: receiving and hand-over point are close together. Space-saving! |

4

4 9

9