|

B.

- 3. |

French fry

(UK: chips) production systems |

|

| 3.1 |

French fry (UK: chips) production systems |

|

|

for

"home-made" quality, |

1

1

|

2

2 |

|

|

Raw French fries (UK:

chips) before deep-frying. |

Pre-fried French fries (UK: chips). Cutting

size here is: 11 x 11 mm. - The fat or oil in DORNOW deep fat fryers doesn't go bad! |

To gain a more profound insight into the production system for the production of "home-made" French

fries (UK: chips), please read:

For more than 40 years, we have been supplying machines and

complete production systems for the production of French fries (UK: chips) (Pre-frying).

We specialize in supplying small to medium capacity systems, which are especially interesting for countries with little or no experience in the field of potato processing.

Now, we are able to apply the experience gained when potato processing was still a novelty in continental Western Europe. Mr. Dornow not only witnessed, but also helped shape these developments. These days, he is happy to pass his experience on to those countries that are inexperienced in these fields.

When designing our systems we place special emphasis on preserving the potatoes' natural flavor. The finished products should have "home-made" qualities. Through industrial mass production, those "home-made" characteristics are frequently lost.

The systems described here are capable of performing every

process completely automatically (raw produce reception - peeling - inspection -

cutting - sorting - cooling), except for the frying process itself. Batch fryers

can be fed and emptied by hand, emphasizing the "home-made" character of the

product.

With the recommended method and by using suitable potato brands,

the following can be produced with our plants:

approx. 65, 125, 250, 500, 750 to 1000 kg/h pre-fried French fries (UK: chips)

with a residual moisture content of approx. 65 %.

The low percentage mentioned allows a fast preparation (pre-frying) in the

catering industry.

In addition, a lot more

post-fried portions can be made by the caterer or restaurateur from such

pre-fried produce than from pre-fried French fries (UK: chips) with, for example,

68% or even 73% water content!

Please note suggestions for further reading at the end of

this section !

2.2

2.2 |

||

| Automatic peeling line with peeling machine 20K-AT-MS. DORNOW has a very large program of peeling machines. Please see section A.-Peeling machines. | French

fry cutting and sorting

machine. In the background: Peeling machine (see photo 2.1) and inspection table. |

3

3

|

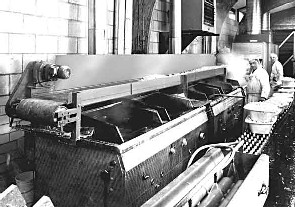

Four 'Industry 300'

(6300) batch fryers, manual operation. Pre-fried

French fries (UK: chips) reach a cooling tunnel (6326) (3

levels,

operating with fresh air via a conveyor belt

(3253) running above the four fryers, and are then

dropped directly into boxes for packaging (in packages

of 5 or 10 kg each). - Capacity: approx. 500 kg/h*. |

|

4

4

|

French fries (UK: chips)

are

removed from batch fryer 'Industry 300' (6300) with a

sifting shovel and placed on the above belt (3253),

then automatically forwarded via cooling

conveyor belt or cooling tunnel to be packaged in

boxes (packages of 5 -10 kg each). The worker on the

photo is taking a look at the French fries. Question:

are

they properly fried? |

|

5

5 |

||

| Potatoes

can be fried in various forms! |

In

order to produce the highest quality and also to be

able to judge the quality of competitors, we can on

demand also supply some laboratory equipment with our

systems. Photo:

Device to determine the water content of potatoes. See also Section L.-23 Laboratory equipment. |

|

7

7 |

8

8 |

|

| In the background, the peeling machine 20K-AT-MS (see above), followed by the inspection table (see section G.), French fry cutting machine Super XA (see section D.), sorting machine 4M (see section F.), washing and dosing bin (see section H.). | Batch fryer "Industry

150" (6301) for the semi-automatic production of

French fries (UK: chips) with a smaller cooling

conveyor belt (6317). - Capacity: approx. 65 kg/h*

pre-fried French fries. |

|

9

9 |

10

10 |

|

|

2 batch fryers type "Industry 300" (6300) with conveyor belt above (3251).- Capacity: approx. 250 kg/h* French fries. |

Single-level cooling

conveyor belt (6317) . |

|

11

11 |

12

12

|

|

|

Semi-automatic production system for French fries (UK: chips) and numerous other deep-fried products (6300 and 3251). Includes cooling conveyor belt (6360). - Capacity: approx. 250 kg/h* French fries. |

French fries (UK: chips)

cutting

machine SUPER XA (0643), mounted on French fries

sorting device 4 M (0850).

- Capacity: to 1000 kg/h. |

|

13

13 |

||

| Cooling tunnel (6322)

for French fries (UK: chips) and similar products. |

Cooling

tunnel for pre-fried French fries (UK: chips), 500 kg/h, during installation. |

|

| Situation

shortly before removal of the French fries (UK: chips), after

approx. 5-7 minutes time of frying (cutting size 11x11

mm). The result: "home-made"

French fries (UK: chips). The

fat/oil (vegetable) does not burn in the deep fat

fryers. It retains its excellent quality.

|

The

fried sticks are thrown

onto the conveyor belt that runs above the deep fat

fryers by

means of special scoops (on the left). They are then fed

automatically into cardboard boxes (containing, e.g. 5

or 10 kg) via a cooling belt. |

|

17

17 |

18

18 |

|

| Peeling machine 20K-AT-MS, automatically working, upstream of a French fry processing machine. Peeling technology: Please see section A.-Peeling machines..... | Continuously

working DORNOW - peeling machine. A large range of smaller and larger roller peeling machines can be found: section A. Peeling Machines, A.-1.1 und A.-1.32. |

|

The following system concepts for the manually

operated, the partially automatic, or the largely automatic production of French fries (UK:

chips) are available:

| 3.1. |

French fries (UK: chips) production systems |

|

(also suitable for frying various other products) |

|

*

= The

output data marked *

are

based

on a residual moisture content of approx. 65

% in the pre-fried product. Advantage: fast preparation (post-frying)

in the catering industry is possible as a lot of water has

already been removed from the product through longer

pre-frying.

This is subject to the condition that suitable

varieties of potatoes are used.

The fat/oil does not go bad (it doesn't burn). You only

have to refill it.

3.1.1

Largely

automatic systems

| System no.

5.3.1.1 |

250*/350 kg of pre-fried French fries (UK: chips)/h and other potato products as fresh produce/optionally as frozen produce |

largely

automated system |

| System

no. 5.3.2.1 |

375*/500 kg of pre-fried French fries (UK: chips)/h and other potato products as fresh produce/optionally as frozen produce |

largely

automated system |

| System no.

5.3.3.1 |

500*/750 kg of pre-fried French fries (UK: chips)/h and other potato products as fresh produce/optionally as frozen produce |

largely

automated system |

| System no.

5.3.4.1 |

750*/1000 kg of pre-fried French fries (UK: chips)/h and other potato products as fresh produce/optionally as frozen produce |

largely

automated system |

3.1.2 Partially automatic systems

| System no.

5.2.1.1 |

250*/350 kg of pre-fried French fries (UK: chips)/h and other potato products as fresh produce / optionally as frozen produce |

system

of simple assembly

|

| System

no.

5.2.1.2 |

250*/350 kg pre-fried French fries (UK: chips)/h and other potato products as fresh produce / optionally as frozen produce |

system

of simple to more manageable assembly |

3.1.3 Systems operated manually

| System no. 5.1.1.1 |

65*/90 kg pre-fried French fries (UK: chips)/h and other potato products as fresh produce / optionally as frozen produce |

system

of simple assembly |

| System no.

5.1.2.1 |

130*/180 kg pre-fried French fries (UK: chips)/h and other potato products as fresh produce / optionally as frozen produce |

system

of simple assembly

|

Further

reading:

| - Q52 |

The Development of an Infant-Potato Processing Production in Areas with Little Experience in the Fields of Processing, Production and Marketing. |

|

On

Peeling |

|

|

- Q122 |

Custom

design DORNOW potato peeling machines ... |

|

- |

A brief description of the continuous multi-disc peeling machines MSS, suitable for the potato and vegetable processing industries, as well as partially suitable for fruit processing and the juice industry. |

|

- Q106 |

A brief description of the DORNOW R-OW series roller peeling machines, suitable for the potato and vegetable processing industries, as well as for the fruit/juice industries. |

|

|

Please also see subsection 1: "Peeling machines" |

|

|

|

|

On

Cutting |

|

|

- Q148 |

Custom design French fry (UK: chips) cutting machines Super XA and KF - also suitable for cutting potato slices |

|

|

|

|

On

Deep-Fat Frying/Fried products |

|

|

-

Q91 |

Large-scale industrial and natural production of French fries (UK: chips). The construction of production facilities for pre-fried French fries (UK: chips) (French fry production) in countries with or without experience in the field of potato processing. |

|

-

Q14 |

Industrial semi-automatic systems for the pre-frying of French fries (UK: chips) and for the deep-fat frying of other products with "Industry 300" or "150" batch fryers. |

|

- Q50 |

Advantages of the manually-operated DORNOW "Industry" series batch fryers, models "150", "151", "300", "301" for the production of pre-fried French fries (UK: chips) and /or potato chips (UK: crisps) as opposed to fully automatic deep-fat fryers of the same capacity. |

|

- Q86 |

French fries (UK: chips) in a microwaveable package, 240 g, frozen |

|

- Q95 |

The colors of pre-fried French fries (UK:chips) and fried potato chip slices (UK:crisps) |

|

- Q134 |

Sensory diagram for French fries (Karlsruhe diagram, revised) |

| - Q147 |

Potato

sizes and their possible use in a French fry (UK: chips) production

plant. |

|

On Cooling /Deep freezing |

|

| - Q44 | Cooling and deep-freezing of industrially pre-fried French fries (UK: chips) and similar products made easy. |

|

Others: |

|

| L. - 23. | |