| A. - 1. |

Peeling machines |

|

| 1.4 |

"Step by step" -"SBS-M" - Blade-type peeling systems (AAS 23) |

Automatic "batch peeling machine(s)", operating without water or with

water mist. Peeling without waste water possible !

| - |

Also suitable for the blade repeeling of carborundum pre-peeled potatoes, |

| - |

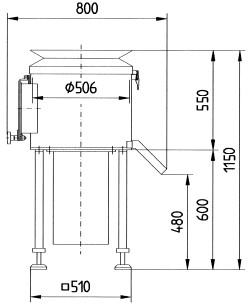

and suitable as independent blade-peeling lines. Diameter of peeling discs: approx. 500 mm |

(Alternative: Subsection 1.2 - Multi-disc peeling machines, continuous operation) |

|

| 1.4.1 |

SBS-M-I blade peeling line, consisting of one blade-peeling unit |

| 1.4.2 |

SBS-M-II blade peeling line, consisting of two blade peeling units |

Capacities: High capacities can be achieved when lines are used for re-peeling or carborundum prepeeled potatoes. Small to medium capacities when potatoes have not been prepeeled.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Alterations reserved

Further Reading:

| Q19 | Fully automatic DORNOW "step by step" blade type peeling systems SBS-M (Machine code: SBS-M-system) |

| Q34 | Continuous blade-type peeling lines |

| Q63 | What are the implications of "peeling without water and waste water" (with mechanical peeling machines) for in-plant practice ? |

| Q92 |

DORNOW

blade peeling

technology |

| Q154 |

A brief description of the continuous multi disc peeling machines MSS, suitable for the pototato and vegetable processing industries, and partially suitable for the fruit processing- and juice industries |

| Q105 |

Continuous multi-disc peeling machines (MSS) as blade type peelers, AM, BM and CM series, blade peeling without waste water |

| Q157 | Peeling questionnaire |

| Q112 | Flavor extraction from potato peel |

| Q104 | Steam peeling - mechanical peeling in small, midium-sized and large industrial facilities - Which peeling method is used where? |

| Q70 | Usability of "waste" peel, especially potato "waste" peel, from mechanically operating dry peeling machines |

For machines 20 M and 20 K: Please see subsection 1.6 - DORNOW batch peeling machines